Light and Medium Section Mill

Light and Medium Section Mill Specification

- Driven Type

- Gear & Electrical

- Automation Grade

- Fully Automatic

- Installation Guideline

- Professional On-site Installation

- Temperature Range

- Up to 1250C

- Usage & Applications

- Industrial Steel Section & Profile Rolling

- Speed

- Up to 110 m/min

- Model No

- LMSM-2024

- Motor Power

- 1100 kW

- Production Capacity

- 30-80 Ton/Hour

- Accessories

- Main Stand, Work Roll, Guide Box, Pinch Roll, Shear, Cooling Bed

- Frequency

- 50 Hz

- Efficiency (%)

- 97

- Type

- Light and Medium Section Mill

- Material

- Mild Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Based

- Drive Type

- Electric Motor

- Voltage

- 380-440 V

- Power

- 1500 kW

- Weight (kg)

- 18000

- Dimension (L*W*H)

- 35 m x 4.5 m x 4.2 m

- Color

- Blue/Grey

- Capacity

- 150000 Ton/Year

- Features

- High Precision, Robust Design, Low Maintenance

- Machine Type

- Rolling Mill

- Surface Finish

- Polished / Painted

- Power Consumption

- 1200 kWh

- Shear Type

- Hydraulic Flying Shear

- Lubrication

- Centralized Electric Lubrication

- Stand Type

- Housingless Mill Stands

- Main Drive Speed Control

- Variable Frequency Drive

- Emission Control

- Fume Extraction System

- Work Roll Diameter

- 450 mm

- Operator Interface

- Color Touchscreen HMI

- Section Profiles Produced

- Angles, Channels, Beams, Flats, Rounds

- Work Environment

- Indoor Industrial Workshop

- Cooling System

- Water Spray / Forced Air

- Electrical Panel

- IP54 Protected

- Tension Leveler

- Included

- Safety Features

- Emergency Stop Switch, Guard Covers

- Cooling Bed Length

- 24 m

- No. of Stands

- 12

- Compliance Standard

- ISO 9001:2015 Certified

- Rolling Type

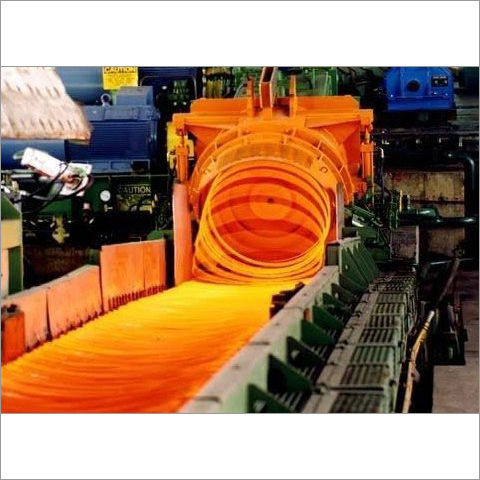

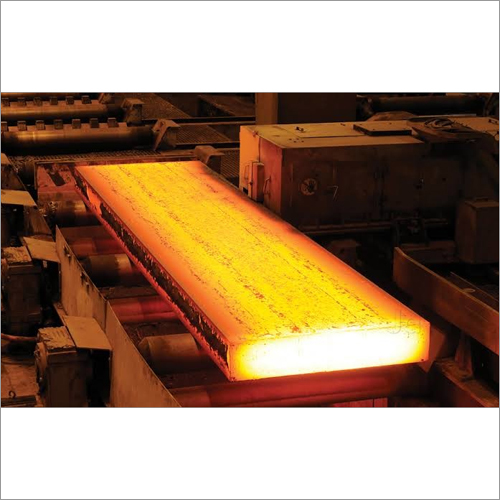

- Hot Rolling

- Input Material Size

- Up to 150 mm x 150 mm billets

Light and Medium Section Mill Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

About Light and Medium Section Mill

Light and Medium Section Mill offered by our company, is usually used to machine flat surfaces, but can also produce irregular surfaces. This mill is most commonly found in shops is a vertical spindle machine with a swivelling head. This is very effective and safe to use. This requires very low maintenance and replacement costs. Light and Medium Section Mill differs from a lathe in that the tool head itself rotates at high speed whereas with a lathe the part itself that is being worked on rotates.

Versatile Production of Steel Sections

The LMSM-2024 mill is engineered to roll a wide variety of section profiles, including angles, channels, beams, flats, and rounds. The system supports billet input sizes up to 150 mm x 150 mm and accommodates a full production range for industrial applications, ensuring flexibility for various project requirements.

Advanced Control and Safety Features

Equipped with a PLC-based control system and a color touchscreen HMI, the mill provides intuitive operation and precise control. Safety is prioritized with emergency stop switches and guard covers, while the IP54-protected panels guarantee reliable performance in industrial workshop environments.

Efficient Cooling and Lubrication

Water spray and forced air cooling systems maintain optimal rolling temperatures, ensuring product quality and equipment longevity. Centralized electric lubrication sustains smooth functioning of moving components, minimizing downtime and enhancing production reliability.

FAQ's of Light and Medium Section Mill:

Q: How does the Light and Medium Section Mill LMSM-2024 improve production efficiency?

A: The LMSM-2024 leverages advanced automation-centralized lubrication, PLC-based control, and a variable frequency main drive-to maximize rolling speed and minimize manual intervention, resulting in consistent quality and high throughput up to 80 tons per hour.Q: What types of section profiles can the mill produce?

A: This rolling mill efficiently manufactures hot-rolled steel angles, channels, beams, flats, and rounds, making it ideal for a diverse range of industrial construction and fabrication applications.Q: When is it recommended to use the LMSM-2024 mill in industrial production?

A: It is best utilized when high precision, robust output, and versatile section profile production are required-particularly in projects demanding up to 150,000 tons yearly and billet inputs up to 150 mm x 150 mm.Q: Where should the mill be installed and operated?

A: The LMSM-2024 is designed for indoor industrial workshops, providing a controlled environment for safe operation and optimal equipment performance. Professional on-site installation ensures proper setup.Q: What is the rolling process in the LMSM-2024 mill?

A: Billets are fed into the mill for hot rolling at temperatures up to 1250C. Material passes through 12 housingless stands, guided and shaped into desired profiles, while cooling and lubrication systems maintain operational integrity.Q: How does the emission control system benefit workshop conditions?

A: Integrated fume extraction mitigates rolling emissions, improving air quality and ensuring compliance with environmental and occupational safety standards.Q: What are the advantages of choosing LMSM-2024 for your steel section manufacturing needs?

A: Users benefit from high accuracy, fast production rates, low maintenance, automated operation, rigorous safety measures, and ISO 9001:2015 compliance-contributing to reliable, efficient, and safe manufacturing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Rolling Mill Plant Workshop Machine Category

Wire Rod Rolling Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Wire Rod Rolling Mill

Control System : PLC Control

Drive Type : Electric

Automatic Grade : Automatic

TMT Rolling Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Hot Rolling Mill

Control System : Other, PLC Based

Drive Type : Electric

Automatic Grade : Automatic

Structure Rolling Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Structure Rolling Mill

Control System : Other, PLC Controlled

Drive Type : Electric

Automatic Grade : SemiAutomatic

Section Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Section Mill

Control System : Other, PLC Controlled

Drive Type : Electric

Automatic Grade : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free