Hot Steel Rolling Mill Plant Workshop

Hot Steel Rolling Mill Plant Workshop Specification

- Automation Grade

- Automatic

- Efficiency (%)

- 85-92

- Accessories

- Furnace, shears, cooling beds, conveyors, gearboxes

- Motor Power

- 50-2500 kW depending on plant size

- Model No

- Custom (as per client design)

- Driven Type

- Electric

- Usage & Applications

- Manufacturing TMT bars, structural steel, re-bars, angles, channels, etc.

- Temperature Range

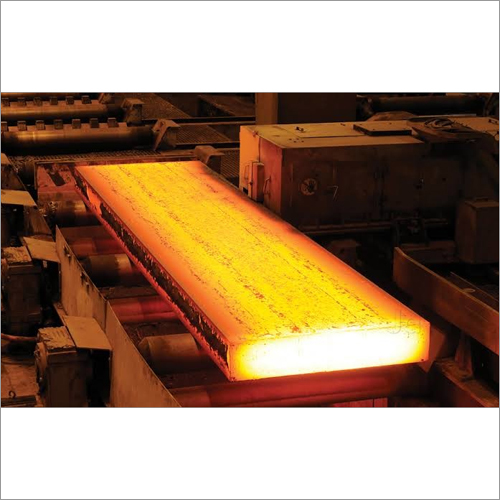

- 850C - 1250C (rolling operation)

- Installation Guideline

- On-site installation & commissioning by experts

- Production Capacity

- 5-30 Tons/Hour

- Speed

- Up to 25 m/min

- Frequency

- 50-60 Hz

- Type

- Hot Steel Rolling Mill Plant Workshop

- Material

- Heavy-duty steel, alloy steels

- Computerized

- Yes

- Automatic Grade

- Automatic/Semi-Automatic

- Control System

- PLC based

- Drive Type

- Electric Motor Driven

- Voltage

- 380-440 V

- Power

- Up to 2500 kW

- Weight (kg)

- Customized, varies by configuration

- Dimension (L*W*H)

- Customized, client-specific

- Color

- Industrial Grey/Blue

- Capacity

- As per requirement, up to 250,000 Tons/Year

- Features

- High precision rolling, robust construction, energy efficient, low maintenance, high production rate

- Surface Finish

- Smooth, uniform, customizable

- Power Consumption

- High efficiency, energy optimized

- Machine Type

- Steel Rolling Mill

- Technical Support

- 24/7 online and onsite support

- Operational Noise Level

- Below 85 dB (with noise control system)

- Safety Features

- Emergency stops, safety interlocks, guards and covers

- Roller Material

- Alloy steel, heat-treated for durability

- Cooling System

- Water-cooled systems for temperature control

- Lubrication System

- Centralized automatic oil/grease lubrication

- Entry/Exit Table Type

- Heavy-duty robust tables, customizable

- PLC Brand

- Siemens/ABB/Mitsubishi (as per client need)

- Roller Diameter

- 300-600 mm (custom as per design)

- Design Standard

- Conforms to ISO, BIS standard practices

- Foundation Requirements

- Heavy foundation with vibration damping as per layout

- Dust Removal

- Industrial dust collectors available on request

- Hydraulic System

- High-pressure hydraulic system for adjustment and safety

- Spare Parts Availability

- Readily available, local and export support

Hot Steel Rolling Mill Plant Workshop Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

About Hot Steel Rolling Mill Plant Workshop

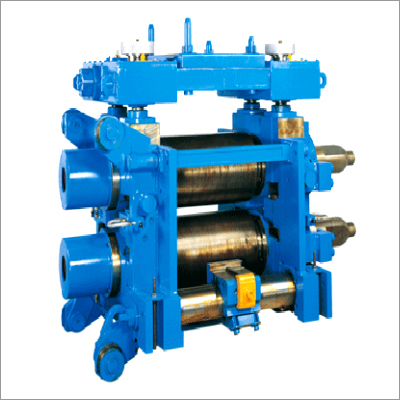

Hot Steel Rolling Mill Plant Workshop is a standalone industrial machine which is commonly used in metalworking industries. It is provided with series of adjacent rollers in between which the metal stock is passed to transform the thickness and maintain the uniformity of the structure. This high performanceindustrial machine helps to improve the strength and toughness of the workpiece.Hot Steel Rolling Mill Plant Workshop availed by us is requires very less maintenance which ultimately results in longer service life.

Precision and Durability in Steel Rolling

Every roller is crafted from alloy steel and undergoes intensive heat treatment, ensuring longevity and resilience during demanding operations. The machines deliver high-precision rolling, thanks to a robust design and advanced PLC control. With heavy-duty, customizable entry and exit tables, each plant layout is tailored uniquely to client needs, allowing for superior adaptability in production lines.

Integrated Systems for Performance and Safety

Automation includes centralized lubrication, water-cooled temperature control, and high-pressure hydraulics for safe, consistent adjustment. The plant's safety features-emergency stops, safety interlocks, and guarding-reduce workplace hazards, while industrial dust collectors enhance air quality when requested. With operational noise maintained below 85 dB, the environment remains comfortable and compliant with regulatory standards.

Comprehensive Support and Custom Solutions

Plant installation is managed by expert teams, ensuring correct foundational requirements, system integration, and commissioning. With readily available spare parts and 24/7 online and onsite technical support, downtime is minimized. The design accommodates a broad voltage range, multiple automation grades, and custom configurations, supporting both local and export demand.

FAQ's of Hot Steel Rolling Mill Plant Workshop:

Q: How does the centralized lubrication system improve maintenance and performance?

A: The plant uses a centralized, automatic oil/grease lubrication system, which ensures optimal lubrication of all critical moving components. This reduces manual intervention, enhances roller lifespan, minimizes downtime, and maintains consistent mill performance, resulting in lower maintenance costs and improved efficiency.Q: What safety features are incorporated into the hot steel rolling mill plant workshop?

A: For operator safety, the workshop includes emergency stop buttons, safety interlocks, guards, and protective covers. These measures prevent accidental access to hazardous zones and enable quick shutdown in emergencies, ensuring compliance with industrial safety standards.Q: When and where are dust collectors required in the rolling mill process?

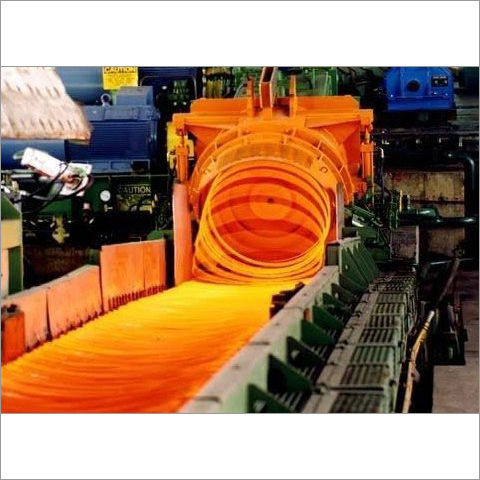

A: Industrial dust collectors are recommended for installations where environmental regulations demand reduced airborne particulates and cleaner air. They can be incorporated upon request and are typically positioned near high-dust generating operations within the workshop to maintain air quality.Q: What is the typical process flow within the hot steel rolling mill plant workshop?

A: The process starts with heated billets/blooms fed onto the entry table, passing through multiple rolling stands where they are shaped by large-diameter alloy steel rollers. The product is cooled, cut (by integrated shears), and finally transported via a robust exit table. PLC-controlled automation ensures precise, repeatable operations.Q: How does the workshop handle variable production requirements or custom design needs?

A: The plant supports customizable parameters, including roller diameter (300-600 mm), production capacity, operating voltage, and physical dimensions, as per client specifications. Control systems from Siemens, ABB, or Mitsubishi, and automation grade (automatic/semi-automatic) are chosen based on the project's scope and output requirements.Q: What are the main benefits of this plant's design for steel manufacturers?

A: Manufacturers benefit from energy-efficient operation (up to 92% efficiency), robust construction for long service life, flexible layout customization, and high production rates (up to 250,000 tons/year). Local and export spare part support, together with 24/7 technical assistance, ensure sustained productivity and minimal downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Rolling Mill Plant Workshop Machine Category

Wire Rod Rolling Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : High strength, Precision engineering, Long life, Energy efficient

Material : Mild Steel

Automatic Grade : Automatic

Surface Finish : Other, Smooth, scalefree rods

TMT Rolling Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : High production capacity, robust design, precise operation, durable finish

Material : Mild Steel

Automatic Grade : Automatic

Surface Finish : Other, Polished / Painted

Structure Rolling Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : High precision rolling, Robust design, Energy efficient

Material : High Grade Steel

Automatic Grade : SemiAutomatic

Surface Finish : Other, Mill Finish

Light and Medium Section Mill

Price Range 100000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : High Precision, Robust Design, Low Maintenance

Material : Mild Steel

Automatic Grade : Automatic

Surface Finish : Other, Polished / Painted

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS