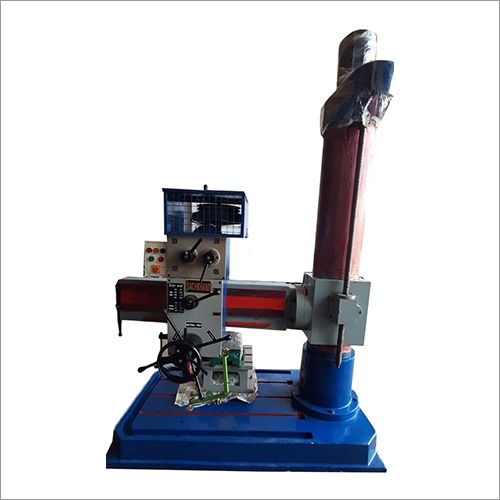

All Geared Radial Drill Machine

Product Details:

All Geared Radial Drill Machine Price And Quantity

- 1 Piece

- 100000.00 - 500000.00 INR/Piece

- 34800 INR/Piece

All Geared Radial Drill Machine Trade Information

- 100 Piece Per Week

- 1 Week

Product Description

All Geared Radial Drill Machine that we are offering is unmatched in terms of design and performance. This is typically used in varied industries including mechanical, automobile, metalworking, among others for various applications including drilling, boring, counter boring, spot facing, tapping, among others. This machine is equipped with precision machine components and parts which are responsible for its longevity and reliable performance. To meet the diverse demands of our customers, we are supplying the All Geared Radial Drill Machine in a plethora of technical configurations and types, and that too at a cost-effective price.

Specification

|

Model |

SDM-40C |

SDM-50B |

SDM-50C |

SDM-65B |

SDM-75B |

SDM-85B |

|

Approx. Weight of Machine |

1850 kg. |

3000 kg |

3500 kg |

4800 kg |

6500 kg |

10,000 kg |

|

Arm Elevator Motor |

0.75 kw |

1.5 kw |

1.5 kw |

2.2 kw |

3.7 kw |

3.7 kw |

|

CAPACITY |

|

|

|

|

|

|

|

Diameter of Column Sleeve |

255 |

310 |

310 |

355 |

405 |

450 |

|

DIMENSIONS OF BASE PLATE |

|

|

|

|

|

|

|

Distance Base Plate to Spindle Max. |

1000 |

1300 |

1300 |

1500 |

1750 |

1800 |

|

Distance Base Plate to Spindle Min. |

225 |

225 |

325 |

300 |

400 |

550 |

|

Drill Head |

SDM-40C |

SDM-50B |

SDM-50C |

SDM-65B |

SDM-75B |

SDM-85B |

|

Drill Power |

2.2 kw |

2.2 kw |

3.7 kw |

3.7 kw |

5.5 kw |

7.5 kw |

|

Drilling Capacity (In steel/ cast iron) |

40/50 |

50/60 |

50/60 |

65/75 |

75/85 |

85/95 |

|

Drilling Depth |

180 |

225 |

250 |

325 |

355 |

400 |

|

Drilling Head Traverse |

675 |

650 |

850 |

1200 |

1300 |

1550 |

|

Drilling Radius Max. |

1050 |

1100 |

1300 |

1700 |

1900 |

2200 |

|

Drilling Radius Min. |

375 |

450 |

450 |

500 |

600 |

650 |

|

Length*Width*Height |

1480*700*200 |

1585*850*200 |

1800*850*200 |

2265*1040*225 |

2650*1180*225 |

3150*1300*250 |

|

No. of Spindle Speeds/ Range (RPM) |

12(56-1000) |

9(45-750) |

12(45-1000) |

12(18-810) |

12(18-810) |

12(16-1250) |

|

Nos of Spindle Feeds/ Range (mm/rev.) |

3(0.1-0.2) |

30.1-0.2) |

6(0.125-1.25) |

6(0.125-1.25) |

6(0.125-1.25) |

6(.08-1.0) |

|

Standard Box Table |

550*420*420 |

550*420*420 |

550*420*420 |

600*500*500 |

600*500*500 |

1000*750*500 |

|

Taper Spindle Nose Socket |

MT-4 |

MT-5 |

MT-5 |

MT-5 |

MT-6 |

MT-6 |

|

Working Surface of Base Plate |

900*680 |

920*830 |

1120*830 |

1500*1020 |

1850*1160 |

2130*1300 |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+